Abstract

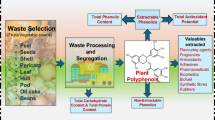

Waste materials in large amount are being generated as distillation waste while essential oil from citrus peels is extracted. These peels are rich in phenolic compounds as well as dietary fibers, a prominent source for nutraceuticals together with bioethanol. In this present study, distillation wastes of three different citrus peels (kinnow, mosambi, and orange) were explored for extraction of phenolic compounds followed by bioethanol production. Ultrasonication-mediated methanolic extract produced the highest yield (19.8–23.1%) of phenolics. Total phenol and flavonoid content in the extract was more in kinnow peels than in mosambi and orange. Antioxidant potency composite (APC) index indicated higher activity for kinnow peels (5.98, 7.67) compared to orange (6.24, 7.69) and mosambi (6.36, 7.88) peels for respective fresh and distilled materials. Residual biomass after saccharification followed by fermentation showed approximately 1.91–2.96 times higher bioethanol production potential in distilled materials compared to non-distilled ones across different peels used. Removal of d-limonene (potential inhibitor of yeast) during hydrodistillation attributed to higher bioethanol production in the distilled materials. The highest ethanol concentration was observed in orange peel (7.89 g/L followed by mosambi (7.16 g/L and kinnow (5.08 g/L). This work primarily focuses on investigating the possibilities for utilization of these wastes into valuable nutraceuticals as well as potential feedstock for bioethanol formation that can be manifested as an important source for value addition and biorefinery.

Similar content being viewed by others

Data availability

Data generated during this present investigation are included in this research article (and its additional/supplementary files). Any requests related to materials should be made to the corresponding author.

References

Matheyambath AC, Padmanabhan P, Paliyath G (2016) Citrus fruits. In: Caballero B, Finglas PM, Toldrá F (eds) Encyclopedia of food and health. Academic Press, Massachusetts, pp 136–140. https://doi.org/10.1016/B978-0-12-384947-2.00165-3

Food and Agriculture Organisation of United Nations (2021) Citrus fruit fresh and processed, Statistical Bulletin 2020. https://www.fao.org/3/cb6492en/cb6492en.pdf. Accessed on 27 May, 2022

Statista Research Department (2022) Production of citrus fruits in India between financial year 2015 and 2021, with an estimate for 2022, by type. https://www.statista.com/statistics/1038920/india-production-of-citrus-fruits-by type/#:~:text=In%20fiscal%20year%202022%2C%20the,million%20metric%20tons%20that%20year. Accessed on 03 September, 2022

Ajila CM, Brar SK, Verma M, Tyagi RD, Godbout S, Valéro JR (2012) Bio-processing of agro-byproducts to animal feed. Crit Rev Biotechnol 32(4):382–400. https://doi.org/10.3109/07388551.2012.659172

Palazzolo E, Laudicina VA, Germanà MA (2013) Current and potential use of citrus essential oils. Curr Org Chem 17(24):3042–3049. https://doi.org/10.2174/13852728113179990122

Transparency Market Research (2021) Essential oil market. https://www.transparencymarketresearch.com/essential-oil-market.html. Accessed 23 April, 2022

M’hiri N, Ioannou I, Ghoul M, Mihoubi Boudhrioua, N, (2017) Phytochemical characteristics of citrus peel and effect of conventional and nonconventional processing on phenolic compounds: a review. Food Rev Int 33(6):587–619. https://doi.org/10.1080/87559129.2016.1196489

Saha A, Basak BB, Manivel P, Kumar J (2021) Valorization of Java citronella (Cymbopogon winterianus Jowitt) distillation waste as a potential source of phenolics/antioxidant: influence of extraction solvents. J Food Sci Technol 58(1):255–266. https://doi.org/10.1007/s13197-020-04538-8

Hilali S, Fabiano-Tixier AS, Ruiz K, Hejjaj A, Ait Nouh F, Idlimam A, Chemat F (2019) Green extraction of essential oils, polyphenols, and pectins from orange peel employing solar energy: toward a zero-waste biorefinery. Acs Sustain Chem Eng 7(13):11815–11822. https://doi.org/10.1021/acssuschemeng.9b02281

Santana-Méridas O, Polissiou M, Izquierdo-Melero ME, Astraka K, Tarantilis PA, Herraiz-Peñalver D, Sánchez-Vioque R (2014) Polyphenol composition, antioxidant and bioplaguicide activities of the solid residue from hydrodistillation of Rosmarinus officinalis L. Ind Crops Prod 59:125–134. https://doi.org/10.1016/j.indcrop.2014.05.008

Tsimogiannis D, Choulitoudi E, Bimpilas A, Mitropoulou G, Kourkoutas Y, Oreopoulou V (2017) Exploitation of the biological potential of Satureja thymbra essential oil and distillation by-products. J Appl Res Med Aromat Plants 4:12–20. https://doi.org/10.1016/j.jarmap.2016.07.002

Santana-Méridas O, González-Coloma A, Sánchez-Vioque R (2012) Agricultural residues as a source of bioactive natural products. Phytochem Rev 11(4):447–466. https://doi.org/10.1007/s11101-012-9266-0

John I, Siddarth G, Kalaichelvi P, Arunagiri A (2017) Characterization of citrus peels for bioethanol production. In: Mohan BR, Sriniketan G, Meikap BC (eds) Materials, energy and environment engineering, 1st edn. Springer, Singapore, pp 3–12

Casabar JT, Unpaprom Y, Ramaraj R (2019) Fermentation of pineapple fruit peel wastes for bioethanol production. Biomass Convers Biorefin 9(4):761–765. https://doi.org/10.1007/s13399-019-00436-y

Lashinsky A, Schwartz ND (2006) How to beat the high cost of gasoline. Fortune European Edition 153(2):40

Choi IS, Lee YG, Khanal SK, Park BJ, Bae HJ (2015) A low-energy, cost-effective approach to fruit and citrus peel waste processing for bioethanol production. Appl Energy 140:65–74. https://doi.org/10.1016/j.apenergy.2014.11.070

John I, Yaragarla P, Muthaiah P, Ponnusamy K, Appusamy A (2017) Statistical optimization of acid catalyzed steam pretreatment of citrus peel waste for bioethanol production. Resour Technol 3(4):429–433. https://doi.org/10.1016/j.reffit.2017.04.001

Dhingra D, Michael M, Rajput H, Patil RT (2012) Dietary fibre in foods: a review. J Food Sci Technol 49(3):255–266. https://doi.org/10.1007/s13197-011-0365-5

Singleton VL, Orthofer R, Lamuela-Raventós RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Meth Enzymol 299:152–178. https://doi.org/10.1016/S0076-6879(99)99017-1

Wang J, Zhao YM, Guo CY, Zhang SM, Liu CL, Zhang DS, Bai XM (2012) Ultrasound-assisted extraction of total flavonoids from Inula helenium. Pharmacogn Mag 8(30):166. https://doi.org/10.4103/2F0973-1296.96581

Brand-Williams W, Cuvelier ME, Berset CLWT (1995) Use of a free radical method to evaluate antioxidant activity. Lwt 28(1):25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26(9–10):1231–1237. https://doi.org/10.1016/S0891-5849(98)00315-3

Benzie IF, Strain JJ (1996) The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal Biochem 239(1):70–76. https://doi.org/10.1006/abio.1996.0292

Apak R, Güçlü K, Özyürek M, Karademir SE (2004) Novel total antioxidant capacity index for dietary polyphenols and vitamins C and E, using their cupric ion reducing capability in the presence of neocuproine: CUPRAC method. J Agric Food Chem 52(26):7970–7981. https://doi.org/10.1021/jf048741x

Seeram NP, Aviram M, Zhang Y, Henning SM, Feng L, Dreher M, Heber D (2008) Comparison of antioxidant potency of commonly consumed polyphenol-rich beverages in the United States. J Agric Food Chem 56(4):1415–1422. https://doi.org/10.1021/jf073035s

NREL (National Renewable Energy Laboratory), CO (2012). Determination of structural carbohydrates and lignin in biomass in the LAP (laboratory analytical procedure). https://www.nrel.gov/docs/gen/fy13/42618.pdf. Accessed 02 April, 2022

Ranganna S (1986) Handbook of analysis and quality control for fruit and vegetable products. 2nd Edition, Tata McGraw-Hill, United States, pp 1112

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428. https://doi.org/10.1021/ac60147a030

Nipornram S, Tochampa W, Rattanatraiwong P, Singanusong R (2018) Optimization of low power ultrasound-assisted extraction of phenolic compounds from mandarin (Citrus reticulata Blanco cv. Sainampueng) peel. Food Chem 241:338–345. https://doi.org/10.1016/j.foodchem.2017.08.114

Sandhu HK, Sinha P, Emanuel N, Kumar N, Sami R, Khojah E, Al-Mushhin AA (2021) Effect of ultrasound-assisted pretreatment on extraction efficiency of essential oil and bioactive compounds from citrus waste by-products. Separations 8(12):244. https://doi.org/10.3390/separations8120244

Adefegha SA, Oboh G, Oluokun OO (2022) Food bioactives: the food image behind the curtain of health promotion and prevention against several degenerative diseases. In Atta-ur-Rahman (Ed) Studies in natural products chemistry, vol 72. Elsevier, Amsterdam, p 391–421. https://doi.org/10.1016/B978-0-12-823944-5.00012-0

Do QD, Angkawijaya AE, Tran-Nguyen PL, Huynh LH, Soetaredjo FE, Ismadji S, Ju YH (2014) Effect of extraction solvent on total phenol content, total flavonoid content, and antioxidant activity of Limnophila aromatic. J Food Drug Anal 22(3):296–302. https://doi.org/10.1016/j.jfda.2013.11.001

Han C, Chen X, Xie W, Zhu Z, Liu C, Chen F, Shen Y (2010) Determination of hexabromocyclododecane diastereoisomers in Sargassum fusiforme and comparison of the extraction efficiency of ultrasonication, microwave-assisted extraction, Soxhlet extraction and pressurised liquid extraction. J Sep Sci 33(21):3319–3325. https://doi.org/10.1002/jssc.201000558

Kam WYJ, Abas F, Hussain N, Mirhosseini H (2020) Comparison of crude extract from Durio zibethinus M. (durian) leaf waste via ultrasound-assisted extraction and accelerated solvent extraction: antioxidant activity and cytotoxicity. Nat Prod Res 34(13):1937–1941. https://doi.org/10.1080/14786419.2018.1564296

Suri S, Singh A, Nema PK, Malakar S, Arora VK (2022) Sweet lime (Citrus limetta) peel waste drying approaches and effect on quality attributes, phytochemical and functional properties. Food Biosci 48:101789

Montero-Calderon A, Cortes C, Zulueta A, Frigola A, Esteve MJ (2019) Green solvents and ultrasound-assisted extraction of bioactive orange (Citrus sinensis) peel compounds. Sci Rep 9(1):1–8. https://doi.org/10.1038/s41598-019-52717-1

Kaur S, Panesar PS, Chopra HK (2021) Standardization of ultrasound-assisted extraction of bioactive compounds from kinnow mandarin peel. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-01674-9

Singh B, Singh JP, Kaur A, Singh N (2020) Phenolic composition, antioxidant potential and health benefits of citrus peel. Food Res Int 132:109114. https://doi.org/10.1016/j.foodres.2020.109114

Sanches VL, Cunha TA, Viganó J, de Souza Mesquita LM, Faccioli LH, Breitkreitz MC, Rostagno MA (2022) Comprehensive analysis of phenolics compounds in citrus fruits peels by UPLC-PDA and UPLC-Q/TOF MS using a fused-core column. Food Chem: X 14:100262. https://doi.org/10.1016/j.fochx.2022.100262

Gómez-Mejía E, Rosales-Conrado N, León-González ME, Madrid Y (2019) Citrus peels waste as a source of value-added compounds: extraction and quantification of bioactive polyphenols. Food Chem 295:289–299. https://doi.org/10.1016/j.foodchem.2019.05.136

Mazor Jolić S, Radojčić Redovniković I, Marković K, Ivanec Šipušić Đ, Delonga K (2011) Changes of phenolic compounds and antioxidant capacity in cocoa beans processing. Int J Food Sci Technol 46(9):1793–1800. https://doi.org/10.1111/j.1365-2621.2011.02670.x

Nickel J, Spanier LP, Botelho FT, Gularte MA, Helbig E (2016) Effect of different types of processing on the total phenolic compound content, antioxidant capacity, and saponin content of Chenopodium quinoa Willd grains. Food Chem 209:139–143. https://doi.org/10.1016/j.foodchem.2016.04.031

Chen Y, Pan H, Hao S, Pan D, Wang G, Yu W (2021) Evaluation of phenolic composition and antioxidant properties of different varieties of Chinese citrus. Food Chem 364:130413. https://doi.org/10.1016/j.foodchem.2021.130413

Gu C, Howell K, Dunshea FR, Suleria HA (2019) LC-ESI-QToF/MS characterisation of phenolic acids and flavonoids in polyphenol-rich fruits and vegetables and their potential antioxidant activities. Antioxidants 8(9):405. https://doi.org/10.3390/antiox8090405

Aguiar L, Marquez-Montesinos F, Gonzalo A, Sanchez JL, Araujo J (2008) Influence of temperature and particle size on fixed bed pyrolysis of orange peel residues. J Anal Appl Pyrolysis 83(1):124–130. https://doi.org/10.1016/j.jaap.2008.06.009

Oberoi HS, Vadlani PV, Madl RL, Saida L, Abeykoon JP (2010) Ethanol production from orange peels: two-stage hydrolysis and fermentation studies using optimized parameters through experimental design. J Agric Food Chem 58(6):3422–3429. https://doi.org/10.1021/jf903163t

Marín FR, Soler-Rivas C, Benavente-García O, Castillo J, Pérez-Alvarez JA (2007) By-products from different citrus processes as a source of customized functional fibres. Food Chem 100(2):736–741. https://doi.org/10.1016/j.foodchem.2005.04.040

Uribe S, Pena A (1990) Toxicity of allelopathic monoterpene suspensions on yeast dependence on droplet size. J Chem Ecol 16(4):1399–1408. https://doi.org/10.1007/BF01021035

Wilkins MR (2009) Effect of orange peel oil on ethanol production by Zymomonas mobilis. Biomass Bioenergy 33(3):538–541. https://doi.org/10.1016/j.biombioe.2008.08.010

Wilkins MR, Grohmann K, Widmer WW (2006) Effect of d-limonene on the fermentation of citrus peel waste. Proceedings of the American Society of Agricultural and Biological Engineers International (ASABE). Paper No. 067007

Sarkar R, Nain L, Kundu A, Dutta A, Saha S (2022) De-oiled citrus peels as feedstock for the production of pectin oligosaccharides and its effect on Lactobacillus fermentum, probiotic source. Front Nutr 9:826250. https://doi.org/10.3389/fnut.2022.826250

Waghmare PR, Khandare RV, Jeon BH, Govindwar SP (2018) Enzymatic hydrolysis of biologically pretreated sorghum husk for bioethanol production. Biofuel Res J 5(3):846–853. https://doi.org/10.18331/BRJ2018.5.3.4

Lavanya AK, Sharma A, Choudhary SB, Sharma HK, Nain PKS, Singh S, Nain L (2020) Mesta potential feedstock for bioethanol production. Energy Sources A: Recovery Util Environ Eff 42(21):2664–2677. https://doi.org/10.1080/15567036.2019.1618980

Patsalou M, Samanides CG, Protopapa E, Stavrinou S, Vyrides I, Koutinas M (2019) A citrus peel waste biorefinery for ethanol and methane production. Molecules 24(13):2451. https://doi.org/10.3390/molecules24132451

Yang P, Wu Y, Zheng Z, Cao L, Zhu X, Mu D, Jiang S (2018) CRISPR-Cas9 approach constructing cellulase sestc-engineered Saccharomyces cerevisiae for the production of orange peel ethanol. Front Microbiol 9:2436. https://doi.org/10.3389/fmicb.2018.02436

Acknowledgements

The authors extend their appreciation to the Head, Division of Agricultural Chemicals, ICAR-IARI, New Delhi, India, for the support. The authors are also thankful to the laboratory staff of Division of Microbiology, ICAR-IARI, New Delhi, India, for their help and support.

Funding

All the authors are thankful to the Indian Council of Agricultural Research, New Delhi, India, for the financial support provided for the execution of the study.

Author information

Authors and Affiliations

Contributions

Rohan Sarkar: literature survey, execution, and manuscript writing; Lata Nain: planning, execution, and guidance; Anirban Dutta: data analysis and manuscript editing; Aditi Kundu: computation work and manuscript writing; Supradip Saha: planning, guidance, data analysis, and manuscript editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable for the present study.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sarkar, R., Nain, L., Dutta, A. et al. Unraveling the utilization feasibility of citrus peel solid distillation waste as potential source for antioxidant as well as bioethanol. Biomass Conv. Bioref. 14, 27379–27391 (2024). https://doi.org/10.1007/s13399-022-03367-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03367-3